At the point when you need a new motor, regardless of whether, for a unique gear application or to supplant a unit that is presently not functional, there is a wide range of alternatives to consider. Effectively distinguishing the most fitting functional boundaries and motor highlights for your application will decide how well that motor performs, how long it endures, and regardless of whether it ends up being dependable and high-esteem speculation for your gear.

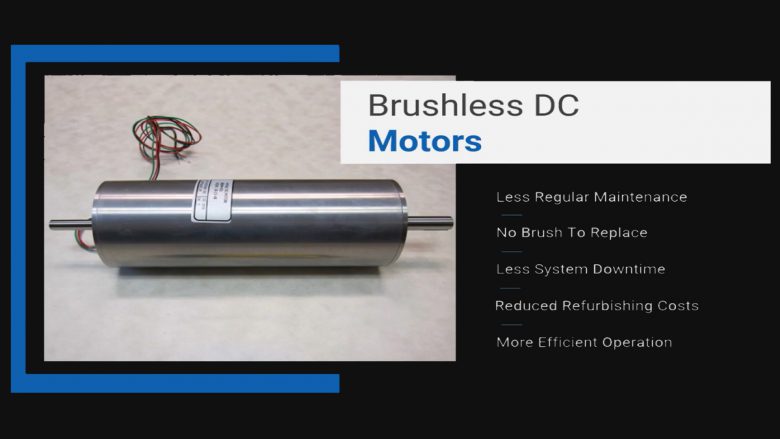

Aside from recognizing the particular sort of motor, regardless of whether it’s a 400 Hz AC acceptance motor for an aviation setting or brushless DC motors for weighty assembling needs, probably the greatest undertaking is deciding if a custom motor is required or then again if a standard one can address novel issues. Resolving the accompanying inquiries will help in that interaction.

Will The Motor Be Subject To Extreme Circumstances?

The motor requires many just necessities to play out a basic occupation of changing over electrical force into force. Be that as it may, if it needs to do as such in outrageous temperatures, where there might be substantial vibration, high dampness, or likely openness to the residue, soil, or different toxins, then, at that point, some unique motor provisions might be required.

It is feasible to modify motors so they are extra impervious to factors that in any case compromise execution. Luckily, a couple of changes can be profoundly compelling and only sometimes necessitate that a motor is re-planned from the beginning.

The expansion of pruned loops, unique winding congregations, acclimations to different materials, or potential changes to the motor’s lodging and protection can be adequate at further developing perseverance under outrageous conditions. A significant number of these changes can be applied without a ton of additional time and cost. Such increments can convey significant profits, as motors with further developed perseverance capacities will require less support and won’t be supplanted as regularly as standard assortments.

Does The Motor Need To Be High-Performance?

Aviation BLDC motors, mil-spec AC motor generators, and substantial modern coordinated motors all need to perform with extraordinary dependability. Such elite motors fulfill severe functional needs and they are generally made to particulars that decide their plan, materials, and different elements.

Superior motors don’t really should be custom, and on account of motors implied for guard and aviation settings, certain industry and application-explicit norms should be met and kept up with. In such cases, a changed or modified motor probably won’t be proper.

For elite hardware that isn’t dependent upon such normalization, motors can be made to custom boundaries that will lift their presentation abilities. Similarly, as with the production of motors that should work in outrageous conditions, changes to materials, the motor’s plan and gathering, and different components can essentially work on the motor’s productivity, speed, life span, and that’s only the tip of the iceberg.

Have Previous Standard Motors Under Performed?

On account of standard hardware that uses standard motors, upkeep and substitutions will be required at some point. Yet, if standard motors are persistently failing to meet expectations and supplanting are required with normal recurrence, a custom motor can tackle this issue.

Various adjustments can add up to a huge expansion in motor life span and execution, which don’t incredibly change the plan of standard units. Numerous AC and brushless DC motor makers can deliver what are basically redesigned renditions of standard motors.

The issue with numerous business off-the-rack units is their restricted functional life because of standard materials and insignificant guidelines that fulfill large-scale manufacturing needs. A custom adaptation of a standard electric motor can be a high-esteem answer for the capacity to outlive standard items should be supplanted again and again.

Picking A Solution

Numerous different components decide if a norm or custom motor is more qualified for a particular application. Regardless of whether you need a servo motor for a mechanical technology model or a frameless BLDC motor to fit inside an extraordinary get-together, it’s valuable to present your presentation necessities to an autonomous motor producer. Getting direction straightforwardly from a mechanical source can save time when matching a motor with an application, which thusly will save support and cost.

Learn more from technology and Nine Ways to Save Money on Home Appliance Purchases.